In the ProRegio project, manufacturing intelligence based methodologies for supporting the co-evolution of the product-services and the related production systems will take place at production network level as well as at single plant level:

At production network level, multi-criteria methods for dynamic production network co-evolution as well as innovative planning tools for tactical scheduling and product allocation will be developed taking existing production capabilities and specific customer requirements for product variants and functionalities into account. Therefore, product variants derived from customer requirements are to be allocated to existing production sites which demand for allocation of production capabilities to production sites. In addition to the allocation of production capabilities, a comprehensive coordination mechanism is to be implemented on the production network level.

At single plant level, methods and technologies to enable the manufacturing and delivery of innovative products and connected services will be developed and implemented in terms of knowledge based engineering tools.

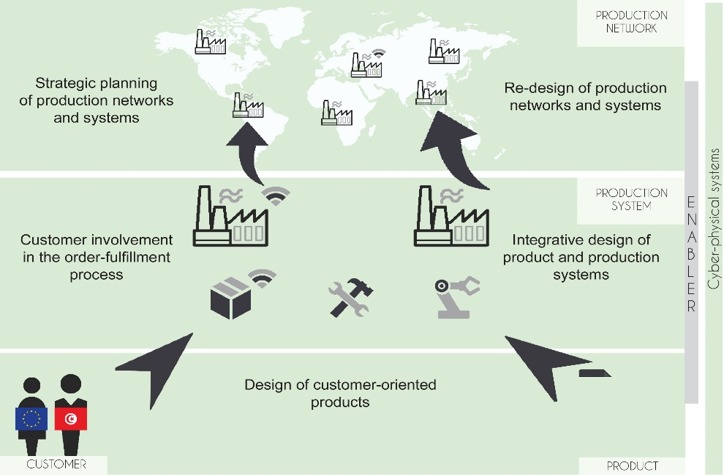

The main idea behind the proposed approach is to develop a holistic methodology for product-service design for customized / frugal products in dynamic global production networks. This methodology will assist to overcome the stated challenges of the European manufacturing industry using ICT as key enabler. The development of this new business approach is based on three major issues (see rows in Figure below):

- design of customer oriented product- services for frugal innovation in a bottom-up development process,

- co-evolution of production systems and networks based on interaction of stakeholders,

- planning and control of production networks and regional production systems to enable ad-hoc re-design.

ProRegio will prepare new products for the ICT companies, new services and advanced tools to develop frugal products for customers especially from emerging countries with dramatically short time-to-markets, to increase operational excellence in plants and networks to improve delivery times and carbon footprint in the manufacturing industry.

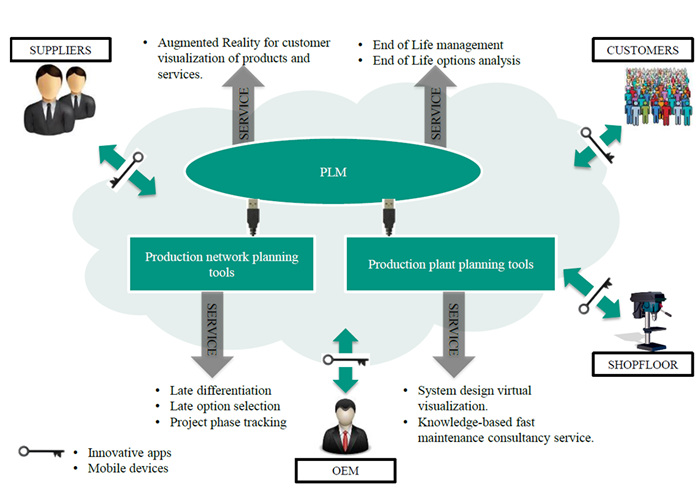

A common framework of cloud-based solutions will be developed in the project to set the basis for smooth data exchange and cross-functionality of the ICT solution.

Thereby, knowledge from shopfloor and from suppliers will be integrated via innovative applications and mobile devices.